Flooring Installation

The best flooring in the world can't do much for you until it's properly installed.

Topics

We share tips for installing a wide range of flooring materials, as well as business insights for installers and contractors.

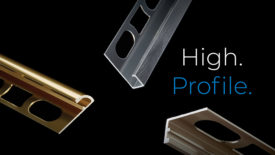

Flooring Installation Products

Information on products for flooring installers and contractors.

Installation Tools & Equipment

Information on tools and equipment that help flooring installers and contractors get the job done.

ARTICLES

If the Floor Is Not Flat, Fix It

Prepping the Substrate Prior to Installing Large-Format Tile

Read More

PAGES

EVENTS

Industry

10/1/24 to 10/3/24

Rosen Shingle Creek

Orlando, FL

United States

CFI + FCICA Annual Convention

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest flooring retail trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing